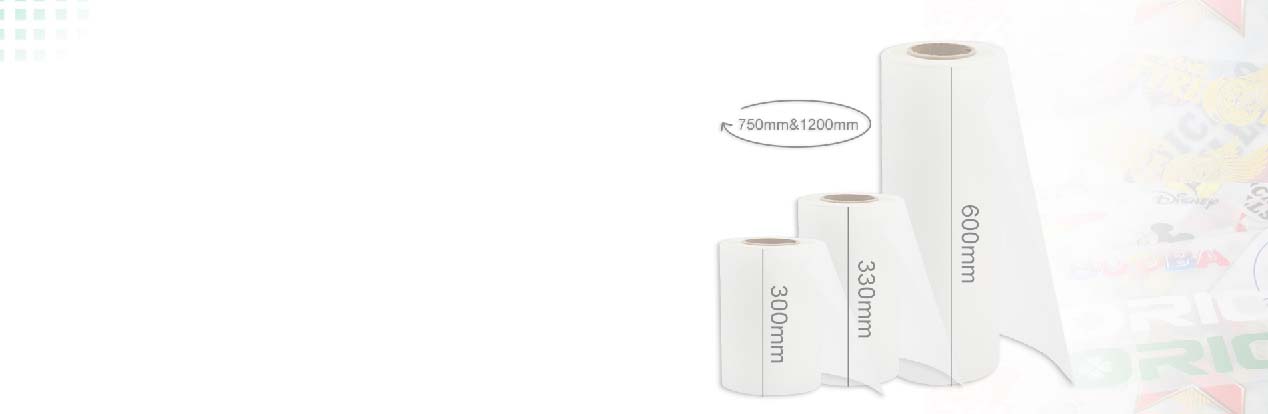

DTF PET Films

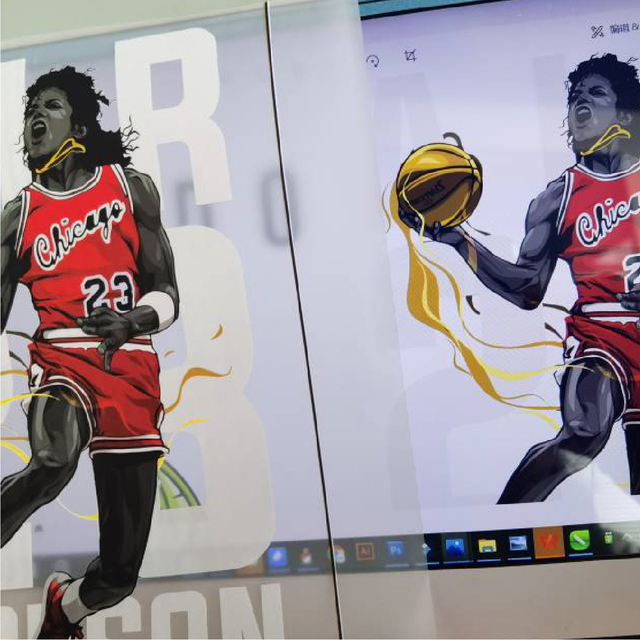

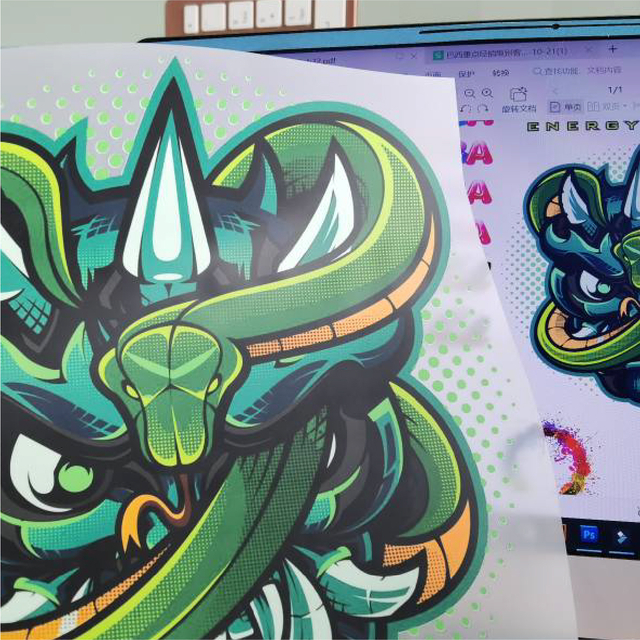

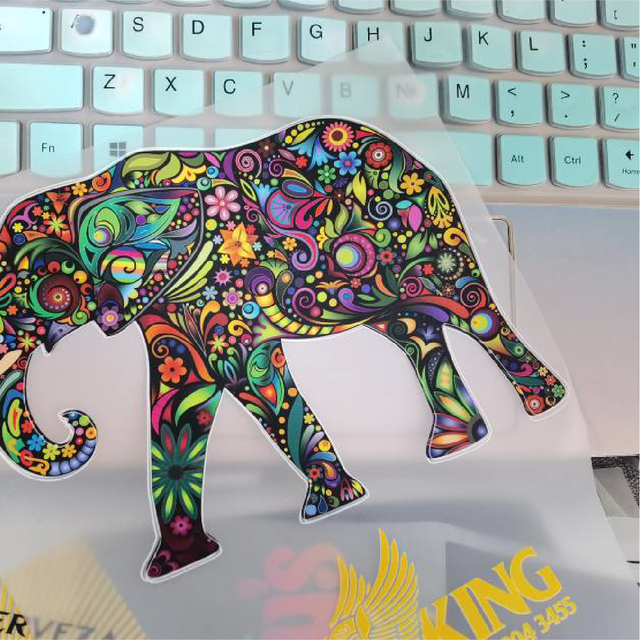

DTF film can be transferred on a wide range of fabrics. Capable of printing to shirts, sweaters, hoodies, pullovers, canvas, denim, and more! Our DTF films have excellent ink absorption for high-precision printing. Use our film you will achieve high-quality, breathable, and smooth prints.

DTF Textile Prinitng Ink

DTF textile printing ink is highly compatible with print Epson heads. You can directly print your designs on different textiles and fabrics using Direct to Film Ink technology.ORIC offers different colors of DTF inks such as W, Y, K, M, C, Or, Gr, and also fluorescence pink & fluorescence yellow.